How Energy-Efficient Is the 50HP Micro-Oil Twin Screw Single-Stage Compressor During Long-Term Operation?

Overview of Energy Efficiency in Industrial Compressors

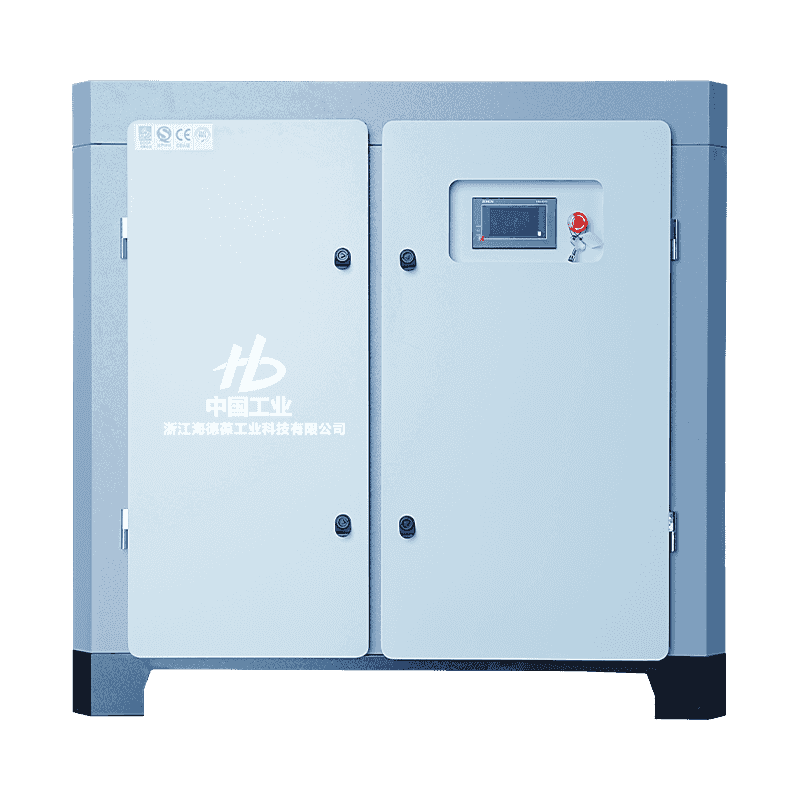

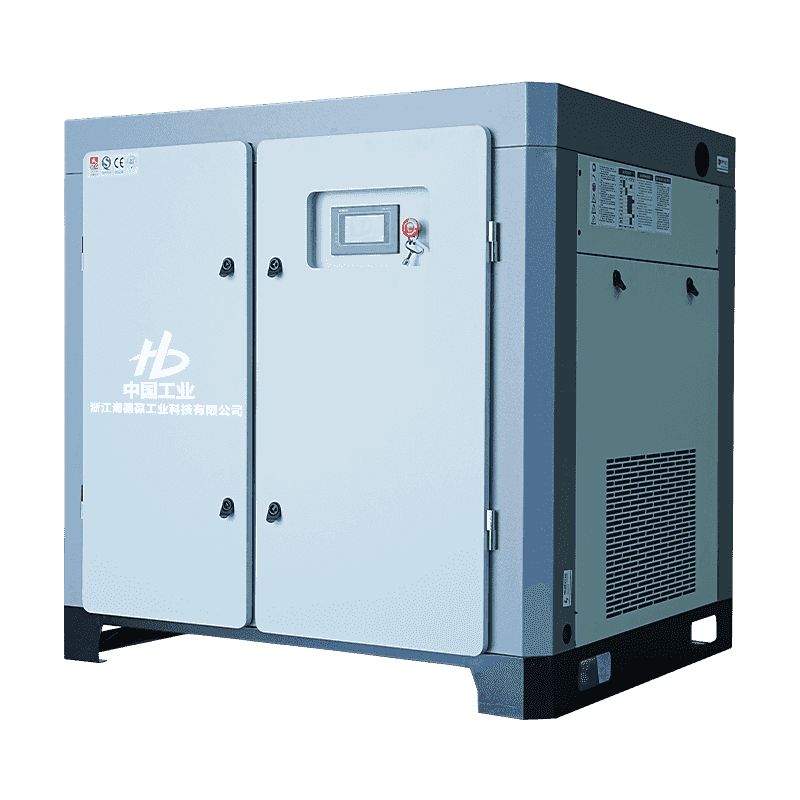

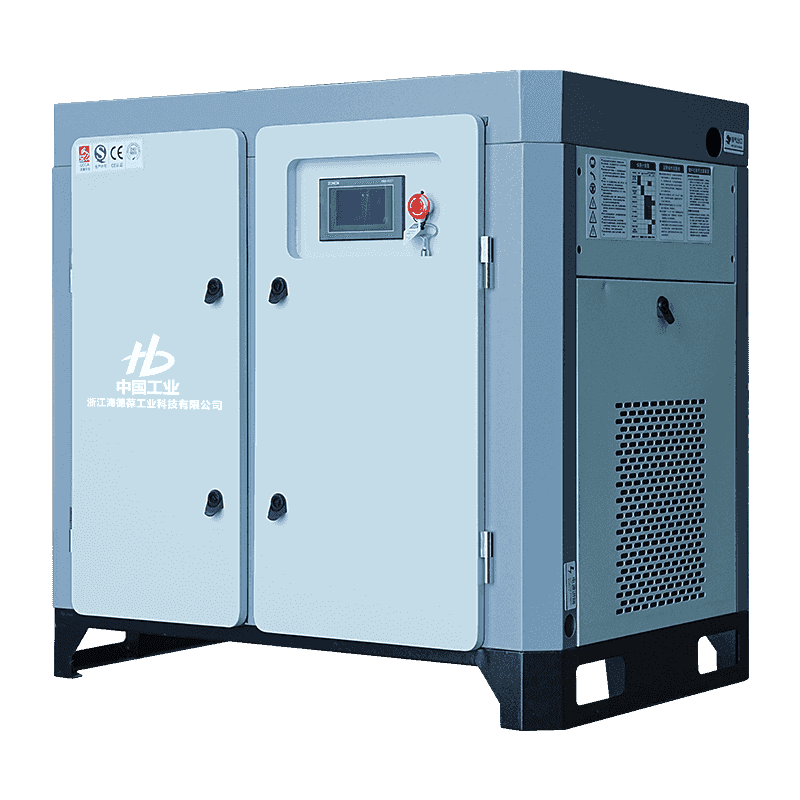

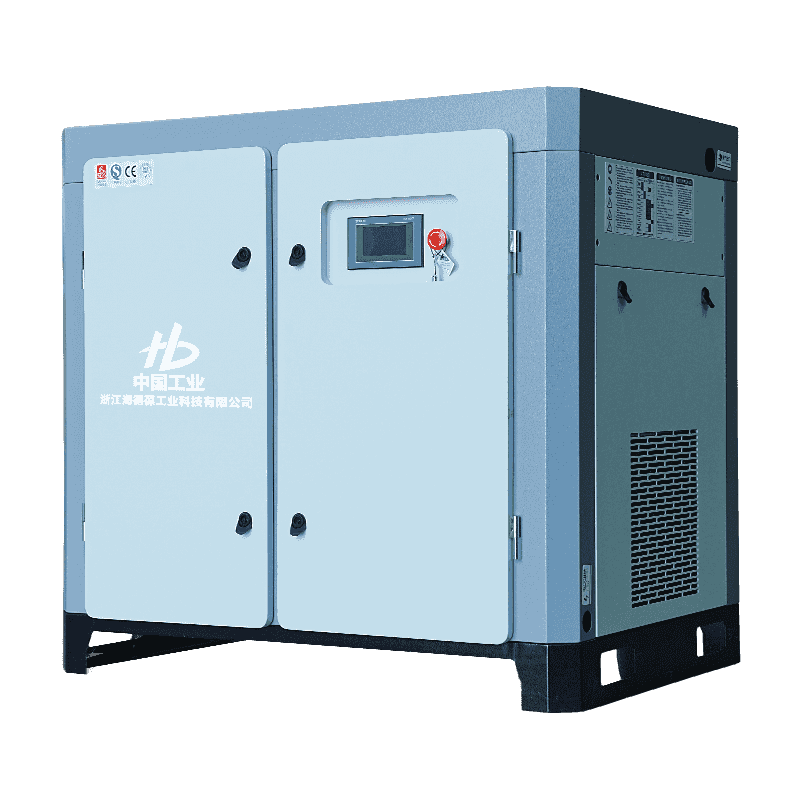

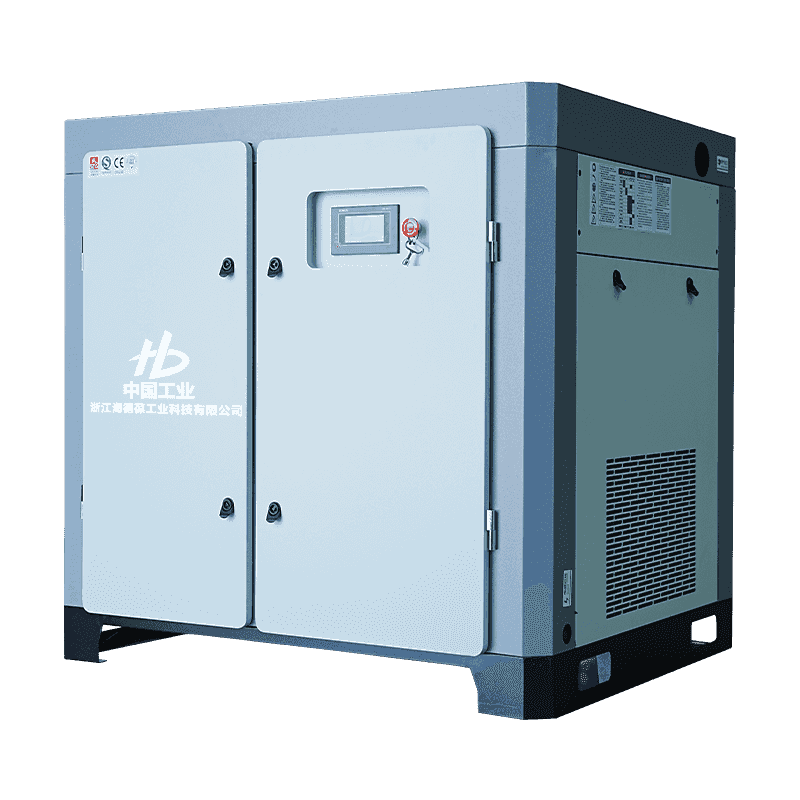

Energy efficiency plays a central role in modern compressed air systems, especially in manufacturing, chemical production, and other sectors that depend on stable and continuous gas sources. The 50HP micro-oil twin screw single-stage compressor produced by Zhejiang Haidebao Industrial Technology Co., Ltd., a professional manufacturer located in Quzhou City, Zhejiang Province, is designed to address the long-term operational needs of such industries. With its micro-oil lubrication technology and single-stage compression structure, the equipment focuses on reducing energy waste and optimizing overall performance. This operational approach not only contributes to reduced operating costs but also aligns with the growing industry trend toward energy-conscious equipment solutions.

Role of Twin-Screw Compression in Energy Conservation

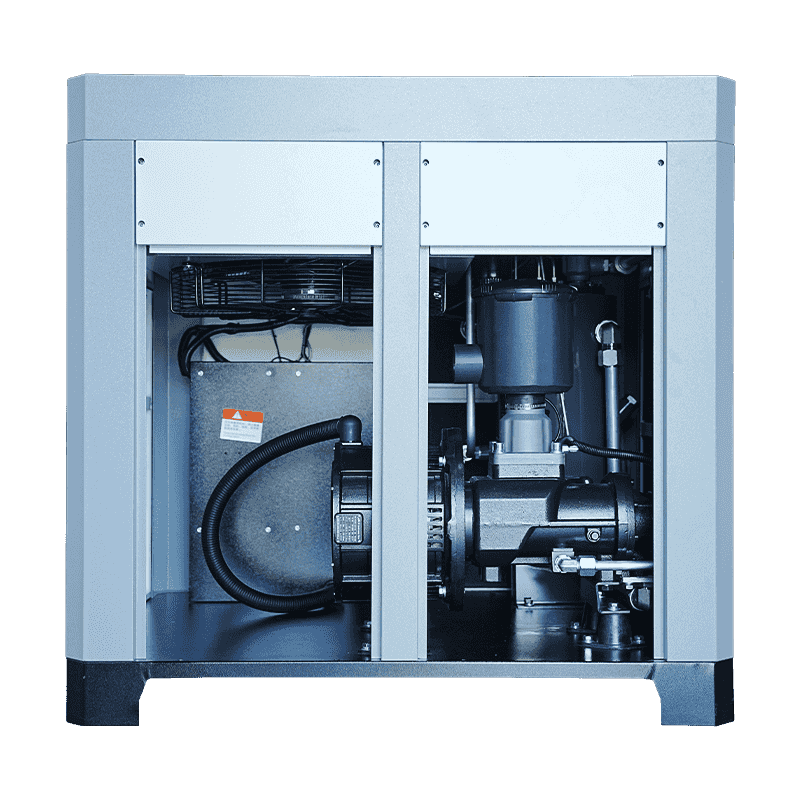

The twin-screw compression system used in the 50HP model is engineered to provide continuous airflow with minimal internal leakage and consistent pressure output. This structural advantage helps maintain energy stability during extended operation. Compared with traditional piston or multi-stage units, the single-stage twin-screw format allows the compressor to deliver the required airflow more efficiently. The stable internal compression process helps reduce fluctuations that may raise consumption. Over extended periods, this steadiness ensures that the compressor performs its tasks without unnecessary power increases, supporting predictable and controlled energy usage in demanding environments.

Impact of the Micro-Oil Lubrication System on Efficiency

Micro-oil lubrication contributes directly to energy efficiency by reducing internal friction and maintaining a stable temperature within the compression chamber. During long-term operation, excessive heat can cause performance loss, but the controlled lubrication layer reduces mechanical stress and helps maintain consistent temperature distribution. This contributes to lowering the workload on the motor, extending operational lifespan, and supporting energy-efficient performance. In addition, micro-oil lubrication provides sealing along the rotor surfaces, minimizing leakage losses, which is a key factor in sustaining energy efficiency over time.

Energy Benefits of the Permanent Magnet Synchronous Motor

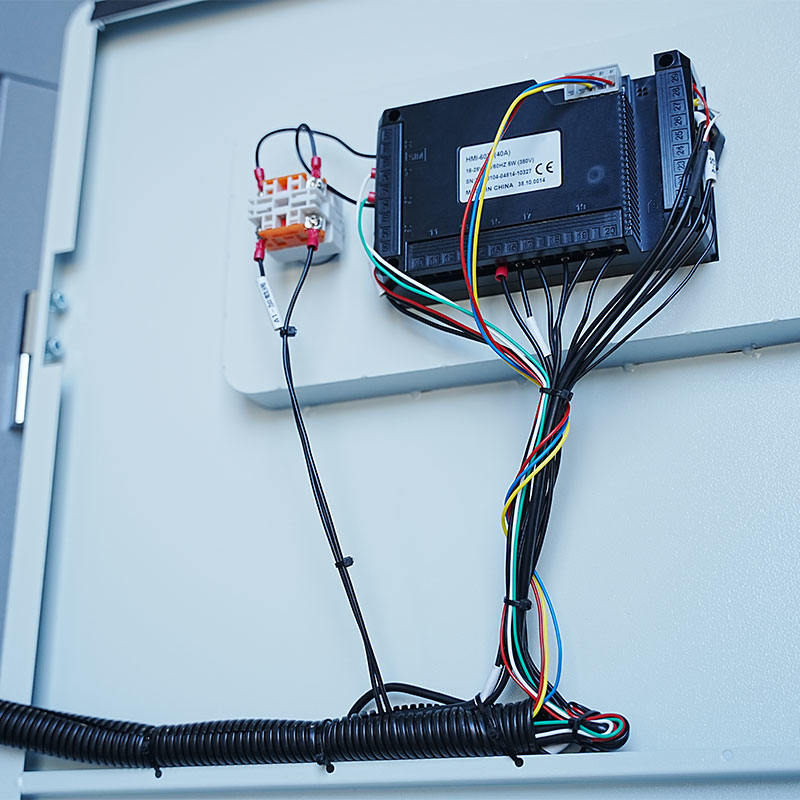

Zhejiang Haidebao Industrial Technology Co., Ltd. integrates a permanent magnet synchronous motor (PMSM) into the 50HP micro-oil twin screw single-stage compressor, adding another dimension to its energy-saving capability. The PMSM design reduces transmission losses associated with traditional induction motors and offers improved operational stability. The motor maintains a higher efficiency level across different speed ranges, which is crucial during long-term operation in environments with variable demand. As a result, the system continues to deliver reliable performance without excessive electrical load, supporting overall energy-conscious operation. This combination of advanced motor technology and optimized compression structure contributes to measurable energy reductions in daily use.

Energy Efficiency Comparison With Conventional Industrial Compressors

To better understand the long-term efficiency of the 50HP micro-oil twin screw single-stage compressor, it is helpful to compare it with conventional single-stage and multi-stage compressors. Many traditional units rely on older motor technologies or mechanical systems with greater wear points. The integration of micro-oil lubrication, PMSM drive structure, and optimized airflow pathways gives the Haidebao design a performance advantage in energy stability across extended operation periods. While output stability, oil consumption, and pressure consistency vary across different compressor types, the 50HP model stands out with its balanced system configuration designed for routine industrial usage. Long-term operation typically reveals substantial differences in energy requirements, making this compressor suitable for facilities seeking predictable electricity consumption patterns.

| Compressor Type |

Energy Stability Over Long-Term Use |

Typical Motor Type |

Lubrication Method |

| 50HP Micro-Oil Twin Screw (Haidebao) |

Stable during continuous operation |

Permanent magnet synchronous motor |

Micro-oil lubrication |

| Traditional Single-Stage Piston Compressor |

More fluctuations in long operation |

Induction motor |

Standard oil lubrication |

| General Twin-Screw Compressor (Older Models) |

Moderate stability depending on usage |

Standard motor |

Conventional lubrication |

Long-Term Operational Costs and Energy Savings

Long-term operation requires an understanding not only of electrical consumption but also of maintenance intervals and the performance consistency of key components. Because the 50HP micro-oil twin screw single-stage compressor minimizes internal friction and heat buildup, it generally reduces the frequency of part replacements and high-temperature shutdowns. The permanent magnet synchronous motor design helps maintain lower electricity usage per unit of compressed air delivered. Over a multi-year timeline, these advantages typically translate into reduced operational expenses. Many industries with high annual runtime requirements, such as chemical plants or large-scale manufacturing lines, benefit from predictable energy utilization, allowing more accurate cost budgeting.

System Performance Stability Under Long-Term Load

Another factor that contributes to the perceived energy efficiency is operational stability under long-term load. The compressor’s internal structure reduces unnecessary cycling and maintains a consistent output range. By minimizing sudden increases in load, the compression system keeps energy demand steady. This characteristic is important for industries where equipment runs continuously for extended shifts. Zhejiang Haidebao Industrial Technology Co., Ltd. has integrated system elements that support this steady-state operation, reinforcing the energy-saving performance of the compressor over extended working cycles.

Summary of Energy-Related Features

The combination of twin-screw compression, micro-oil lubrication, and permanent magnet synchronous motor technology allows the 50HP micro-oil twin screw single-stage compressor to maintain an energy-efficient profile during long-term operation. Its system design centers on stability, reduced mechanical wear, and optimized airflow management. While actual energy savings vary depending on the operational environment and workload, the compressor’s structure allows industries to manage their compressed air production with greater efficiency and predictability.

English

English Español

Español عربى

عربى